|

|

| current issue |  |

past issues |  |

send a letter/news |  |

address update |  |

advertise |  |

about us |  |

alumni home |

Features

Farming's New LandscapePage 2 of 4

|

Because of the state's farming heritage and the strength of UNH's agricultural programs and outreach, many of New Hampshire's farmers are UNH alumni. Some attended college planning to return to the farm. Others sought opportunities in agribusiness, their degrees opening doors to careers in animal nutrition, farm economics and plant science.

Highlighted here are three different types of family farms, all run by UNH alumni. Each farm is considered progressive for its use of the latest technologies to enhance production, and their owners know the risks and benefits of working with living things.

Despite the hardships of the industry, Taylor suggests three reasons farmers stick to their business. "There's a lot more to it than cash return," he claims. "One, you get a chance to involve your whole family--family members can have a direct impact on the economic well-being of the whole operation. Two, you can work outdoors in a self-defined job. And three, you don't have to suck up to anybody."

Standing on the rocky slope of his family's Barrett Hill Farm, Matt LeClair looks like a guy who has spent a lot of time down at the gym lifting weights. His powerful arms curve away from his compact body; his small hands are dense and meaty. But what built his strong frame over the last nine years is lifting rocks from these New Hampshire hills and the steady labor of his highly physical occupation.

Since his graduation from the Thompson School in 1990 with an associate's degree in animal science and a minor in plant science, LeClair has toiled 365 days a year—with the exception of one week this past January for his wedding and a quick honeymoon—to turn his parents' farm in Mason, N.H., into a productive beef, fruit and vegetable enterprise.

LeClair, who manages about 300 acres, is considered a progressive farmer because he is up-to-date on new methods and eagerly incorporates them into his farm. Besides the remarkable red mulch, LeClair makes use of "high tunnels," easily constructed, portable plastic greenhouses which are just high enough for a farmer to walk down the middle.

"Using a high tunnel means that a farmer can double the growing season—one month in the spring and two months in the fall," says Wells. "There's almost complete disease control because they are very dry. And there's more yield per unit area." Efficient use of the land is vital to New England farmers who vie for land with developers. "Farmland is going fast," says LeClair. "You can't compete with developers for prime agricultural areas, so you're forced to look for higher value consumer-oriented crops."

Marketing his strawberries and a wide variety of vegetables at stands around the area, LeClair relies, in part, on consumer desire for locally grown fresh produce. "The availability of produce in the supermarket has grown dramatically," says extension fruit specialist Bill Lord. But the produce in the supermarket lacks a family with a stake in how it was grown, he says, while home-grown agricultural products represent a certain kind of "goodness."

The farm has been in LeClair's family since the 1920s. In the '30s it burned—LeClair credits a granite outcropping for attracting the lightning that struck the farm three times in the last 100 years—and the family found it cheaper to relocate to Massachusetts. They returned in the 1960s and farmed the land part-time.

"I honestly feel that this is a noble occupation," he says. "There's a lot of history on the farm and the land I'm working, and I feel like I'm connecting a little bit with the people who were working it 200, 300 years ago." LeClair plans to clear an additional 20 acres this year and is excited to have his wife, Beth, as a partner. "She loves it," he says. As for her nursing career, he acknowledges, "It's always good to have something else in your back pocket."

It's a blustery mid-November day at Graymist Farm on the banks of the Connecticut River in Groveton, N.H., and Nancy '76 and Gordon '74 Gray have just begun the 4 p.m. milking. Nancy works efficiently in the seven- by 25-foot recessed pit as she readies the milking parlor—three end-to-end stalls on either side of the pit—for the onslaught of 86 cows, bovine wetnurses to modern society.

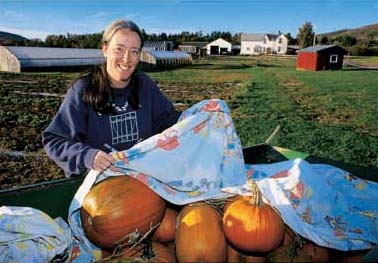

Nancy McGee Gray '76 covered pumpkins at Graymist Farm last fall to ward off the frost. Nancy McGee Gray '76 covered pumpkins at Graymist Farm last fall to ward off the frost. |

Each cow has a name and a number: a name for Nancy's affectionate attention and a number for the computer. Molly, a first-calf heifer, stands placidly in the cubicle undaunted by the cachugachug of the milking units. Nancy accesses data on Molly by pressing buttons on a small box affixed to each stall. "1S tells me that 179 is her number," she says. "2S tells me how many pounds of milk she gave, 32.6 pounds, and 24S tells me it took her 4.9 minutes to give me that milk." All this information and more, progeny data, maternal characteristics, fertilization timetable, are stored in the small gray PC which sits in their barn's office: the Gray's access to high technology in this world of mud, manure and milk. Nancy doesn't need the computer to tell her the cows' names, though. She knows them by heart.

Page: < Prev 1 2 3 4 Next >Easy to print version